With special guest author: Lachlan Fuge.

I asked Lachlan Fuge if I could share this blog that he posted on LinkedIn on our website as it speaks to a couple of points in relation to energy efficiency, gas turbines and mechanical engineering and how they are being deployed in the real world.

Enjoy:

How to tell a Boeing 737MAX from an older 737

Today I thought I’d share a bit of knowledge about the Boeing 737 family, specifically the newest generation: the 737MAX. Using photos from my travels and career in aviation, I’ll demonstrate four main ways to distinguish Boeing’s most advanced narrow body airliner from the reliable and successful predecessors that paved the path for its success. Follow along with the photos to read about the 737MAX’s new advanced features.

Here is a factory-new 737MAX departing Boeing King County Airfield in Seattle, USA. With its two engines instantly heating the ambient air up to nearly 1,060°C, two thick lines of blurred and expanded air shoot out from behind the aircraft as it propels itself into the air.

The older CFM56-7B engine of a 737NG (top) compared to the CFM LEAP-1B engine of a 737MAX (bottom). An obvious feature of the 737MAX’s engines is the shiny new Carbon Fibre-Reinforced Polymer (CFRP) fan blades, which are not only lighter, but stronger. These, along with new Ceramic Matrix Composite (CMC) materials inside the engine’s core, allow the CFM LEAP-1B to be up to 15% more fuel efficient and 40% (yes, really!) quieter than the older CFM56. The LEAP-1B’s larger size also allows for larger fan blades, which cause it to have a bypass ratio of 9:1, almost double the CFM56-7B’s, which allows a maximum rated thrust of 29,320lbs of force. Smooth chevrons along the back of the engine delay the mixture of hot core air with cold ambient air, resulting in a quieter engine for both passengers and those below.

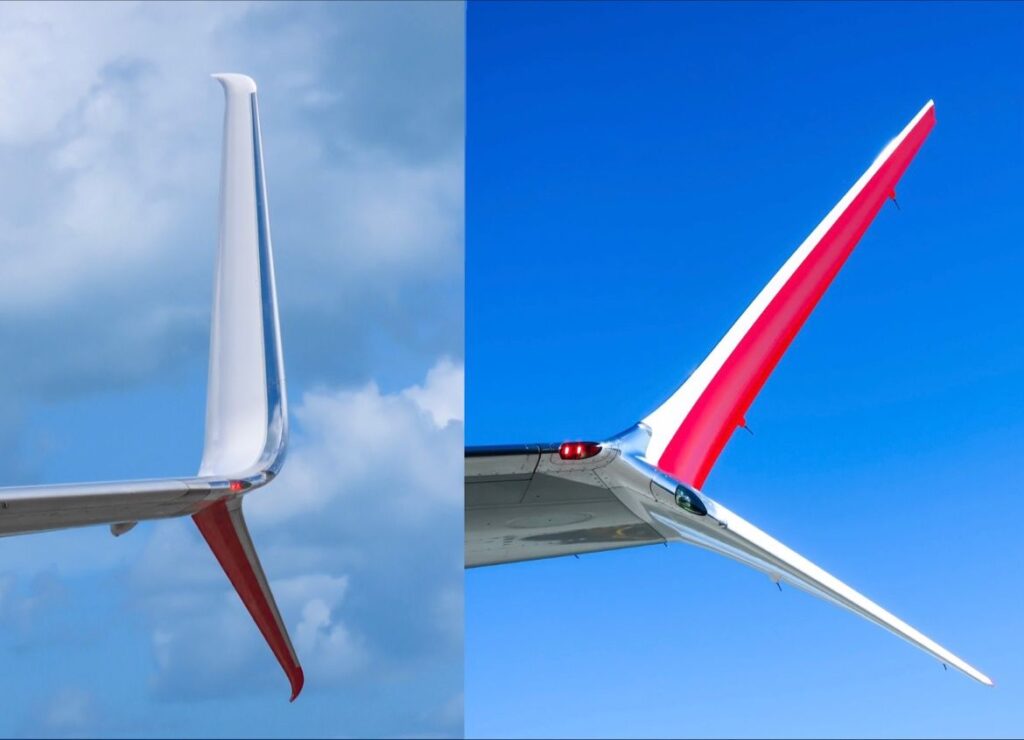

The most obvious tip for identifying a 737MAX, by far, is the new Advanced Technology (AT) winglet. The 737MAX was the first Boeing narrowbody family to be designed with winglets, and the new AT winglet is the most fuel efficient winglet ever installed on an aircraft. The difference between the older “split scimitar” winglet of the older 737NG (left) and the AT winglet of the 737MAX (right) is the angle at which they’re installed. While the split scimitar winglet is at almost a 90° angle, the AT winglet was designed to follow the optimum path for the air passing around it, using something called “Natural Laminar Flow Technology” [see note below]. Aside from being mounted at a shallower angle, the AT winglets are also smoothened and designed to slice through the air without disturbing it as much as older winglets.

Like much of the 737MAX’s technology, the new empennage (tail section) was borrowed from Boeing’s highly advanced and successful 787 Dreamliner program, which entered commercial service in 2011. The 737MAX’s new low-drag APU exhaust cone (top) is more aerodynamic than the older 737’s APU exhaust (bottom).

The last change you will notice when seeing a 737MAX on the ground is the raised nose landing gear, which gives more ground clearance for the engines. Notice the lengthened strut of the 737MAX (right) compared to a 737-300 (left).

Closing thoughts from Andrew

Aeroderivative gas turbines tend to follow aircraft engines in terms of adoption of new technologies. I’d like to understand more about the technical differences between the older and newer engine types and the potential for some of these technologies to bring heat rate improvement to the LM2500 and LM6000 fleets.

I’ll put my mechanical engineering hat on to answer the natural laminar flow question. Laminar flow occurs when a fluid (or gas) flows past a surface in smooth layers (like a deck of cards being pushed sideways). This is distinguished from turbulent flow, which occurs when the particles start to roll around and mix in eddies and swirls. Air passing over an aerofoil will start as laminar flow at the leading edge of the aerofoil and then move to turbulent along the aerofoil. The transition point is a function of speed, surface roughness, viscosity and density. Turbulent flow is less efficient than laminar flow. The AT winglet is trying to manage surface roughness and localised air velocity (particularly in the corners) to minimise disturbances to air flowing over the winglets.