Hello Safeguarders, it’s your favourite clean energy advisors, Arche Energy, here to blog about natural gas production, LNG and how the Safeguard Mechanism fits in.

This is the fourth blog in our “Addressing the Safeguard Mechanism” series.

If you rank the Safeguard facility data by reported emissions from highest to lowest Gorgon, Ichthys LNG and Woodside’s North West Shelf Project share the podium.

These projects collectively reported some 21.4 million tonnes CO2-e in 2021-22.

Power sector emissions are excluded from the facility data due to the sectorial baseline, as explained in our first Safeguard blog “The Safeguard Mechanism Explained”, so you won’t see thermal power plant (be it coal or gas) this list.

Gorgon

Let’s look a little closer at Gorgon with it being at the top of the list and all.

Principal sources of emissions from Gorgon include reservoir carbon dioxide, gas turbine emissions (power and LNG compressor drives) and flaring.

Reservoir emissions are naturally occurring carbon dioxide, a component of the gas stored underground in the reservoir.

This carbon dioxide is drawn up from the reservoir with the methane through the well and is removed from the product gas by a series of amine scrubbers (acid gas removal).

Gorgon is reported to have CO2 content of 14% by volume.

Gas turbines (consuming natural gas) are used to drive the compressors used in the liquefaction process and also to generate power used at the LNG facility.

Flaring of gas occurs either due to stranded gas (i.e. gas produced when the LNG trains are down) or as part of safety systems (i.e. if a sudden release of gas from the plant is necessary).

Conventionally, reservoir emissions are released to the atmosphere, however, a condition of approval for the Gorgon project was that 80% of the CO2 removed from the reservoir is to be captured and stored.

Chevron have developed a sequestration field in geological formations under Barrow Island.

Although Chevron have had their fair share of teething problems with their sequestration systems, they state that over the period August 2019 to July 2022 over 7 million tonnes have been sequestered against a production adjusted baseline and net emissions of 8.3 Million tonnes.

The CCS plant is sized for 3.3 to 4 Million tonnes per annum and the LNG plant is sized at 15.6 Million tonnes (LNG) per annum.

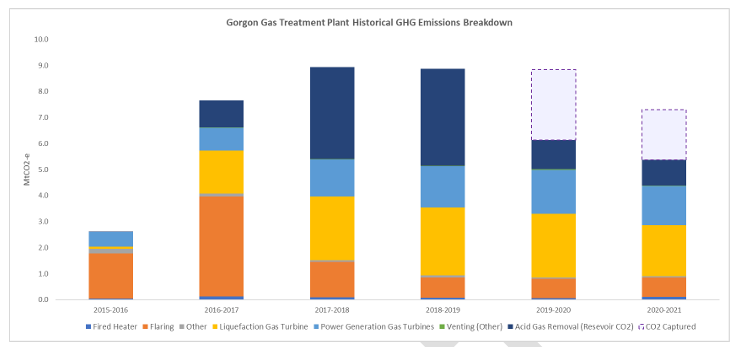

The chart below is sourced from the draft Gorgon Gas Treatment Plant Greenhouse Gas Management Plan, submitted to the Western Australian EPA on 17 August 2022.

The chart shows an interesting history of the sources of emissions and their improvements such as emissions reductions over time.

Looking at the chart you can see flaring reducing as the plant is commissioned and carbon capture improving as bugs are ironed out of the system.

And over to the Sunshine State

If I look down the list further, I come to the three Curtis Island LNG facilities of APLNG, QCLNG and GLNG, each of which have emissions in the order of 2 million tonnes CO2-e per annum.

The sources of emissions from these plants will be similar to Gorgon, with the key difference being that the acid gas removal stream is substantially lower due to the LNG plant being remote from the gas fields (requiring gas to be processed to pipeline standards in the field) and their being little to no entrained carbon dioxide in coal seam methane.

We then go further down the list and get to the first of the Queensland coal seam methane gas projects, QGC upstream, at 1.1 million tonnes per annum (production adjusted baseline).

This is where Queensland shines as coal seam methane has a naturally low CO2 content and very pure methane (CH4) content.

QGC upstream reported 0.84 Million tonnes per annum from 2021 to 2022.

Sources of emissions from coal seam methane fields include fugitive emissions (particularly from water gathering systems), flaring of gas and gas consumption for compression operations and remote power generation.

Shell have committed to end routine flaring of gas and keeping the methane intensity of their operations below 0.2%.

If QGC upstream is combined with QCLNG with a capacity of 8.5 Mtpa LNG, the total well to ship emissions reported in 2021 to 2022 are 0.84 upstream and 1.85 for the LNG plant, summing to a total of 2.68 million tonnes per annum and an intensity of 0.32 tonnes of CO2-e per tonne of LNG export capacity.

This compares to Gorgon at 8.3 million tonnes CO2-e per annum and an export capacity of 15.6 and an intensity of 0.53 tonnes of CO2-e per tonne of LNG export capacity.

There is obviously a capacity factor that needs to be applied to these two intensity estimates (so please don’t take them as Gospel).

With this in mind, the difference is an indication of the value of low carbon intensity reservoirs such as coal seam methane over some of the higher CO2 content conventional reservoirs and the data also proves that Queensland is just the best.

Special rules for LNG exports

The Australian Greens managed to negotiate in special rules for facilities exporting LNG, requiring that new facilities offset 100% of their reservoir emissions through the Safeguard Mechanism, thereby raising the 80% standard set by Gorgon, which means new faculties are going to have to meet this more onerous emissions reduction target.

Solutions

Clearly geological sequestration has a lot to offer conventional gas projects; particularly when coupled with enhanced oil recovery, that is using pressurised CO2 to displace residual oil or gas from depleted reservoirs.

Typically the basins with strong oil and gas geology also have formations suitable for carbon storage (if the reservoir can hold a wee little molecule like methane, it can hold something 2.75 times heavier like a carbon dioxide molecule).

Electrification allows compressors and other plant to be powered from renewable or other low carbon intensity power sources. Post combustion capture and storage is also an option for LNG gas turbines.

Where power and compression gas turbines are operating in open cycle, conversion to combined cycle and cogeneration allows more efficient use of the energy released from combustion of the gas.

Efficiency is always king when it comes to emissions, reducing fugitive emissions (it’s all lost revenue), monetising flare gas or its heat, improving LNG train thermodynamic efficiency and other efficiency measures are typically “no regrets”.

Shameless self promotion plug

Arche Energy, the happiest clean energy consultants in Australia, can help your organisation reduce its carbon intensity with one of our fixed price carbon and energy reduction reviews.

Arche Energy is Australia’s first choice in gas turbine owner’s engineers.

With substantial oil and gas, gas turbine, and carbon capture energy consulting experience, Arche stands ready to assist our clients meet their safeguard and emissions reduction goals.

About the Author

Andrew Murdoch is the Managing Director of Arche Energy and is is a long term energy industry participant, advisor and energy nerd.